Transformers

Continental is one of the big players in the automotive supplier industry. At the location in Wetzlar sophisticated telematic systems are developed for applications all around the world.

The view is magnificent. On one of the finer days in February, Scott Stegert receives us in his office on the sixth floor of the administration building. From the big windows you look over Wetzlar where Stegert arrived almost nine months ago. The native US citizen finds it marvelous although – or rather because – he previously worked for Continental in Chicago, Shanghai and Tokyo. Now, he has been Vice President of the “Agile Campus Wetzlar” since June 2017. He feels quite at home in Germany and is fascinated by the region and by his company anyway.

Forming a corporation-wide network

There is a reason why Wetzlar is not called a location but an “Agile Campus” in his title, as Scott Stegert explains: “Our company has more than 220,000 employees at almost 430 global locations. But we rather think and act in business units which are distributed and interconnected all over the world. That means, no location stands on its own but is always part of a corporation-wide network.” This sounds ambitious, and that’s exactly what it is – particularly in view of the fact that big organizations are traditionally considered to be sluggish and difficult to maneuver.

Continental seems to render this physical law inoperative. At least, if one takes a closer look at the activities at their location in Wetzlar. Here, staff works on almost all vehicle controls and driver assistance systems, which will increasingly facilitate our current and future mobility. The spectrum ranges from infotainment systems, telematics and connectivity to intelligent transport systems and autonomous driving. In Wetzlar, high-performance systems are developed and designed to meet all specific requirements on the global markets. Since the technology of these systems is developing at high speed, the company has to respond accordingly: flexible, fast and agile.

Transforming to an “Agile Campus”

„Thus, the goal is not only to meet the changes impelled by products and markets but also to be one step ahead of them,” Sten-Olaf Wilkening, Director Innovation & Communication points out. In order to achieve this goal, a transformation process was set up within the organization which ensures a more flexible cooperation between the various technology and business units: “We want to invoke the kind of corporate culture which is successfully demonstrated by primarily small start-ups,” Wilkening says: “They focus on new methods and collaboration models which permit greater flexibility and more agility.”

The comparatively young manager Scott Stegert initiated this transformation at the location Wetzlar but did not decree its implementation from above. Specific measures were identified and mapped out with all members of staff in the course of a Transformation Conference. So-called “Change Agents” see to it that all employees are taken along and that promising measures are also transferred to other locations.

New paths in development and cooperation

Wetzlar is the first location where this is consistently put into practice. “In principle, it is as if you changed the oil while the motor is running,” Stegert says, knowing quite well how demanding it is to start a regeneration process that will leave the beaten track. But the process proves to be highly beneficial because the essential point is how to make even better use of existing qualities and qualifications in an extremely active sector of technology in the future. Internally, this applies to the interaction of the corporation’s business units worldwide, but also in the cooperation with external suppliers and partners.

Sten-Olaf Wilkening, who has been working for the enterprise for more than 17 years, knows about the qualities at the location and in the region: “Traditionally, Wetzlar’s strong point is the system integration of optics, electronics, and mechanics. But even here it is regarded as imperative to break fresh ground in development and cooperation.” Perhaps this will result in partnerships as they have never been seen before in the automotive industry. After all, no one anticipated that Google would contribute to the development of self-driving cars or that the German postal service would sell their own e-car.

Enormous requirements in the automotive industry

The intricacy of electronic components and control systems, however, has caused a permeability of sales and procurement markets as we have never known before. On the one hand, this opens up opportunities for new partnerships, but on the other hand it also means that the enormous requirements of the automotive industry have to be fulfilled. The standards here regarding quality, function and safety are higher than those of any other industry.

Lutz Hofmann can tell a thing or two about it. He is head of the division Product Verification and Validation in Wetzlar. Or simply put: He is responsible for the verification of required specifications and for the validation of systems at the end user’s. “These encompass, for example, climate tests at temperatures from -40 to +80°C or vibration tests on coarse cobblestones roads,” Lutz Hofmann explains. “Functional tests running for hours, days and weeks make sure that a command is actually carried out as desired at the touch of a button or that a touch-sensitive screen is working correctly. Furthermore, there are voice-activated controls, which do not only have to listen attentively but also have to do the right thing. And this applies to up to 200 different country variants per system.”

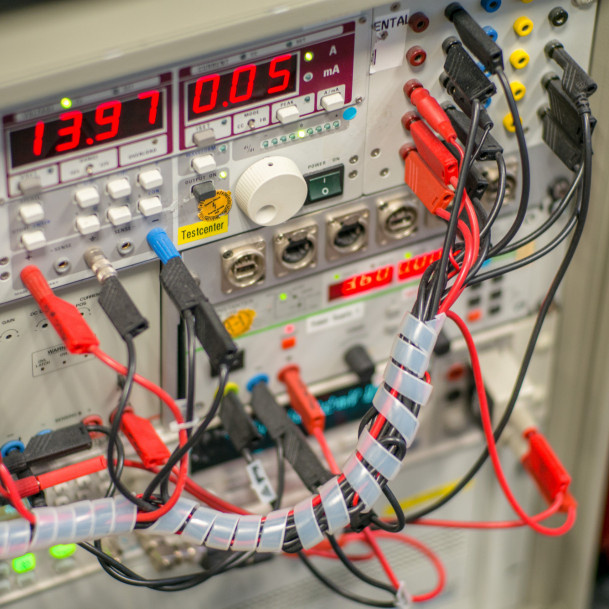

Automated and interconnected test cycles

Despite the increasing intricacy and quality requirements, it is crucial not to lose too much time with test cycles. But Lutz Hofmann does not appear to be frenzied at all. Quite the contrary. Fully in command of any situation, he stands among semi- and fully automated test facilities which are stoically doing their work: cameras which film the touch of a button, evaluate the executed command and document errors in real-time; microchips which trace the movements of a vehicle by using optics, radar or mapping data, check the mobile Internet reception or simulate a ride through the Gotthard Tunnel; and finally, some compact supercomputers which are intended to control all electronic operations in future vehicles.

“A lot of what we tested under real conditions in the field in the past can now be checked in an automated way or in virtual reality. Digital networks offer splendid opportunities: the colleagues in Singapore can now analyze tests conducted in Wetzlar – and vice versa. In the end, however, the decisive testing authority are our highly qualified employees,” Lutz Hofmann points out. “Without them, without their know-how, we would achieve nothing.”

The “Agile Campus” starts with education

In Continental’s Training and Education Center the fertile ground is laid for the kind of know-how that is needed in the company. It is no surprise that the concept of the “Agile Campus” finds its direct expression here. “In former times we trained much more mere / pure electronics technicians or mechanics but this has radically changes in the course of the technological development,” says training instructor Stefan Henß. Today, software developers and software architects are in demand who are able to plan, implement and test extremely sophisticated Embedded Software. For this reason, Continental collaborated with the University of Applied Sciences for Central Hessen (THM) in drawing up the dual study course “Computer Engineering”. Most apprentices grasp at the chance to continue their education permanently or even go studying.

Apprenticeship at Continental in Wetzlar enjoys an excellent reputation – and having experienced the very committed trainers in action one understands why. The trainers support and challenge their apprentices wherever they can. Electronic test benches, which are developed by apprentices, will be used directly at customers’ sites. This means, apprentices work with practical orientation and are educated with reference to specific processes – in particular when apprentices or dual students have to apply for eight weeks of field work abroad at one of Continental’s locations around the globe where they have to assert themselves.

Employees who bring groundbreaking products onto the market

Scott Stegert who insists on accompanying us through the Training and Education Center is delighted. For the Training Center creates what probably distinguishes the “Agile Campus” the most: alert and dedicated employees who bring groundbreaking products onto the market by applying the latest methods and the most modern means. This is how you succeed in staying one step ahead in the fast-paced automotive business. Today and in future.

Scott Stegert, der es sich nicht nehmen lässt, uns beim Rundgang durch den Ausbildungsbereich zu begleiten, ist begeistert. Denn hier entsteht das, was den „Agile Campus“ bei Continental wahrscheinlich am meisten auszeichnet: nämlich agile und engagierte Mitarbeiter, die mit neuesten Methoden und modernen Mitteln wegweisende Produkte auf den Markt bringen. So kann es gelingen, der schnelllebigen Zeit im Automobilgeschäft immer einen Schritt voraus zu sein. Heute und in Zukunft.

Company Profile:

Continental AG is a listed technology group in the automotive supplier industry based in Hanover, Germany. The company develops groundbreaking technologies and services for sustainable and interconnected mobility of people and their goods. Currently, Continental has more than 220,000 employees at almost 430 locations in 56 countries.